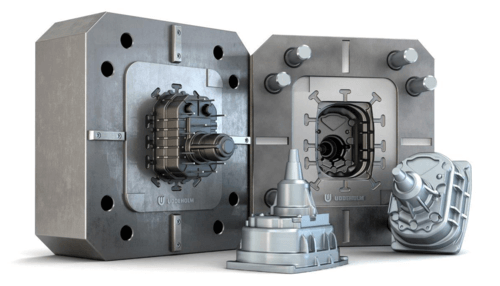

Casting Dies – High Pressure Die Casting

High Pressure Die Casting offers the most efficient method to convert molten metal directly into a finished, complex-shaped component with exceptional precision. It works by injecting molten metal—whether aluminum or zinc—into a high-grade, hardened steel mold.

Once injected, the molten metal is allowed to solidify under constant high pressure before the part is ejected. This process ensures tight tolerances, superior surface finish, and high repeatability.

At VSRM TECHNOLOGIES, we specialize in manufacturing up to 660 TON Pressure Die Casting (PDC) moulds, delivering performance, strength, and durability to meet your most demanding production needs.